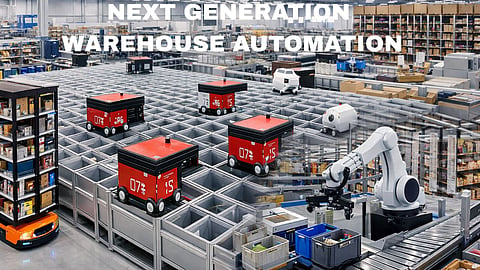

Insight: Goods-to-Person Automation Gains Momentum in Next Generation Warehousing

Goods-to-person (GTP) automation is rapidly reshaping warehouse and logistics operations as companies race to improve efficiency, accuracy, and resilience in the face of rising e-commerce demand and ongoing labor shortages.

Unlike traditional fulfillment models where workers walk long distances to retrieve items, GTP systems bring inventory directly to stationary pickers using robotics, conveyors, or automated storage and retrieval systems (AS/RS).

The result is faster order fulfillment, reduced labor strain, and better use of warehouse space.

The renewed interest in GTP automation is being driven by a combination of factors: same-day delivery expectations, rising warehouse wages, and the need for scalable operations during seasonal peaks.

By minimizing human travel time, GTP systems can increase picking productivity by two to three times compared to manual processes, while also improving order accuracy.

Industry's Early Adopters

One of the most visible real-world adopters of GTP technology is Amazon, which has spent more than a decade integrating robotics into its fulfillment network. The company’s robotic-driven fulfillment centers use mobile robots to transport shelving units - known as pods - directly to human pickers.

AI Transforms the Modern Warehouse: From Storage Hub to Smart Nerve Center

This approach has allowed Amazon to store more inventory in the same footprint and shorten order processing times, especially during high-volume shopping events. The company continues to expand these systems globally as part of its long-term logistics strategy.

In the grocery and food retail sector, Ocado has become a benchmark for highly automated GTP operations. Ocado’s customer fulfillment centers rely on dense, grid-based storage systems where thousands of robots move across a lattice structure to retrieve totes and deliver them to picking stations.

This model enables rapid processing of online grocery orders while maintaining strict accuracy and freshness requirements. Several international retailers now license Ocado’s technology to support their own automated distribution centers.

Another prominent example comes from manufacturers and third-party logistics providers adopting cube-based automation from AutoStore.

AutoStore’s GTP system uses a compact grid of stacked bins accessed by robots that travel on top of the structure. The solution is particularly attractive for facilities with limited space, as it maximizes storage density while reducing energy usage.

Automotive suppliers, electronics distributors, and pharmaceutical companies have all deployed AutoStore systems to streamline order fulfillment and support omnichannel distribution.

New Technology New Challenges

Despite the benefits, GTP automation is not without challenges. High upfront investment costs, system integration complexity, and the need for skilled maintenance teams can slow adoption for smaller operators. However, falling robotics costs and the rise of automation-as-a-service models are lowering barriers to entry.

As supply chains continue to evolve, GTP automation is increasingly viewed not as a futuristic option, but as a practical response to today’s operational pressures. With proven implementations across e-commerce, retail and industrial logistics, the technology is poised to become a standard feature of next-generation warehouses.

Read More: 4-Way Pallet Shuttles Poised to Change the Game for Warehouse Automation